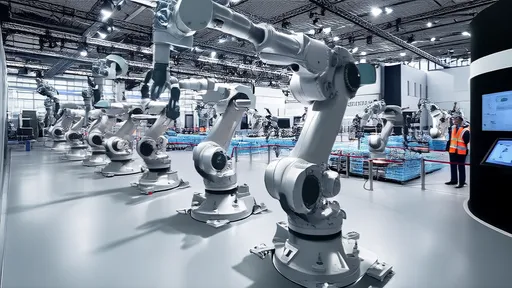

The clatter of machinery echoes through Czech factories with renewed intensity these days, but it's a sound less of human labor and more of automated precision. In a remarkable economic shift, the Czech Republic has catapulted itself into the global top five for industrial robot density, a metric that measures the number of robotic units per 10,000 human employees in the manufacturing sector. This isn't merely a statistical achievement; it's the culmination of a strategic, multi-faceted transformation that is fundamentally reshaping the nation's industrial landscape and its position in the global supply chain.

For decades, the Czech industrial identity was synonymous with skilled, hands-on craftsmanship, particularly in its automotive heartland. However, the pressures of global competition, a tightening labor market, and the relentless push for efficiency have compelled a dramatic pivot. The journey to this elite robotic status began not as a sudden revolution, but as a necessary evolution. Following the 2008 financial crisis and spurred further by the economic disruptions of the pandemic, Czech manufacturers faced a stark reality: to survive, they had to become faster, more flexible, and less dependent on a finite human workforce. The government, recognizing this imperative, began to foster an environment conducive to technological adoption through targeted incentives and support for research and development in automation technologies.

The driving force behind this robotic surge is, unsurprisingly, the automotive industry, the traditional bedrock of the Czech economy. Giants like Škoda Auto, a subsidiary of the Volkswagen Group, and the Hyundai and Toyota-Peugeot-Citroën (TPCA) plants have become showcases of advanced automation. Walking through a modern Czech car plant today is to witness a ballet of synchronized machines. Massive robotic arms perform flawless welds with superhuman consistency, autonomous guided vehicles (AGVs) glide silently along pre-programmed paths delivering components, and sophisticated vision systems conduct quality inspections with an acuity beyond human perception. This isn't just about replacing manual tasks; it's about creating an integrated, data-driven production ecosystem where every process is optimized for peak performance.

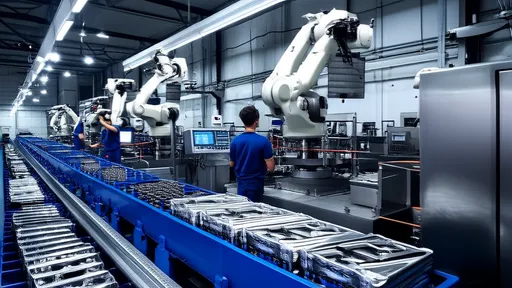

Yet, to attribute this success solely to the automotive sector would be a significant oversight. A silent but powerful wave of automation is sweeping through other key Czech industries. The metalworking and machinery sector, long a bastion of traditional machining, is now populated by CNC systems and robotic milling centers that operate around the clock. The plastics and rubber industry utilizes robots for intricate injection molding and precise assembly tasks. Even the food and beverage industry is embracing automation for packaging, palletizing, and hygiene-critical processes. This diversification proves that the Czech embrace of robotics is a broad-based industrial strategy, not a niche application.

Behind the gleaming robots on the factory floor lies a complex web of economic drivers that made this transition not just possible, but imperative. The most pressing catalyst has been a severe and persistent labor shortage. With unemployment rates hovering at historic lows, finding workers, especially for repetitive or physically demanding factory roles, has become a monumental challenge for employers. Automation presented a viable solution to this human resource crisis. Furthermore, the intense pressure from global clients, particularly German automotive OEMs, for higher quality, lower costs, and just-in-time delivery forced Czech suppliers to invest in technology to meet these exacting standards. The need for enhanced productivity and competitiveness in a market dominated by low-cost Eastern producers and high-tech Western rivals left automation as the only logical path forward.

The societal and economic implications of this robotic density are profound and double-edged. On one hand, it has solidified the Czech Republic's reputation as a high-tech, reliable manufacturing hub, attracting further foreign direct investment. Productivity metrics have seen a notable uptick, and the ability to maintain 24/7 production cycles has made Czech companies more resilient to demand fluctuations. However, the fear of widespread technological unemployment is a palpable concern. The classic narrative of robots displacing human workers is unfolding, particularly for low-skill, repetitive assembly line jobs. This has created a pressing need for a massive reskilling and upskilling initiative. The new factory floor requires fewer manual laborers and more robot programmers, maintenance technicians, data analysts, and systems integrators.

In response, a collaborative effort between the government, educational institutions, and private industry is underway to future-proof the workforce. Technical universities, such as the Czech Technical University in Prague (ČVUT) and Brno University of Technology, are expanding their curricula in mechatronics, robotics, and artificial intelligence. Vocational training centers are being modernized to equip workers with the skills to operate alongside, and manage, their automated counterparts. This transition is less about humans versus machines and more about humans and machines collaborating in new, more complex symbiosis.

Looking ahead, the Czech automation journey is far from over. The current focus on physical robots is rapidly merging with the digital realm of Industry 4.0. The next frontier involves the integration of the Internet of Things (IoT), where robots become nodes in a vast, interconnected network. Artificial intelligence and machine learning are being deployed to move beyond pre-programmed tasks towards predictive maintenance and self-optimizing production lines. The goal is the creation of the "smart factory"—a fully digitalized, adaptive, and autonomous production environment where data drives every decision.

The Czech Republic's ascent into the global top five for robot density is a testament to a nation strategically navigating the turbulent waters of the 21st-century global economy. It is a story of transformation from a legacy of manual skill to a future built on digital and mechanical intelligence. The path has not been without its social challenges and economic dislocations, but the commitment appears unwavering. The humming robots in Czech factories are no longer just tools; they are the new workforce, and their rising density is the clearest signal yet that the country is betting its economic future on a highly automated, technologically advanced, and fiercely competitive industrial base. The world is watching, as this Central European nation provides a compelling case study in how to harness the power of automation for national economic advancement.

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025