In the quiet Swedish town of Skellefteå, just 200 kilometers south of the Arctic Circle, a quiet revolution is taking place that could reshape Europe's industrial future. Northvolt, the continent's most ambitious battery startup, has officially inaugurated what industry analysts are calling Europe's largest battery factory—a sprawling complex that represents not just a manufacturing facility, but a statement of intent in the global race for clean energy technology.

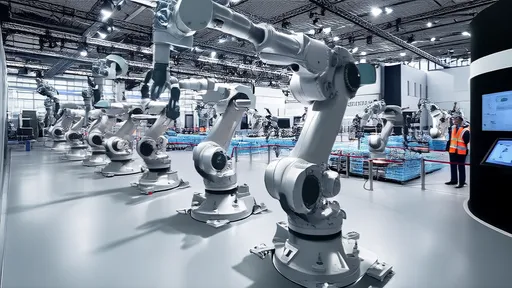

The Northvolt Ett facility, whose name simply means "Northvolt One" in Swedish, stands as a testament to European determination in the face of Asian dominance in battery manufacturing. With its gleaming production halls stretching across an area equivalent to 70 football fields, the factory represents more than just physical infrastructure—it embodies Europe's strategic pivot toward energy independence and technological sovereignty. The scale of the operation becomes apparent when considering that the facility's annual production capacity could eventually power over one million electric vehicles, fundamentally altering the automotive landscape across the continent.

What makes Northvolt's achievement particularly remarkable is the timeline and context of its development. Founded in 2016 by two former Tesla executives, Peter Carlsson and Paolo Cerruti, the company has moved from PowerPoint presentation to industrial behemoth in just five years—a pace that defies conventional wisdom in capital-intensive manufacturing. The factory's location in northern Sweden, while seemingly counterintuitive, leverages the region's abundant renewable energy resources, with approximately 95% of the facility's power coming from hydroelectric and wind sources. This positions Northvolt as not just a battery manufacturer, but as a pioneer in genuinely sustainable industrial production.

The significance of Northvolt Ett extends far beyond its production statistics. European Commission officials have privately described the facility as a cornerstone of the European Green Deal and the bloc's broader industrial strategy. With the European Union planning to phase out combustion engine vehicles by 2035, the availability of locally produced, sustainable batteries has become a matter of economic security. The factory represents Europe's answer to what policymakers have termed "the battery gap"—the concerning dependency on Asian manufacturers for the crucial technology that will power the continent's clean transportation future.

Production at Northvolt Ett represents a departure from conventional battery manufacturing in several key aspects. The company has developed what it calls a "prismatic cell" design that offers higher energy density and improved safety characteristics compared to traditional formats. More importantly, Northvolt has placed circular economy principles at the heart of its manufacturing process. The company has committed to using 50% recycled material in all new battery cells by 2030, with an on-site recycling facility capable of recovering up to 95% of valuable metals like nickel, cobalt, and manganese from used batteries.

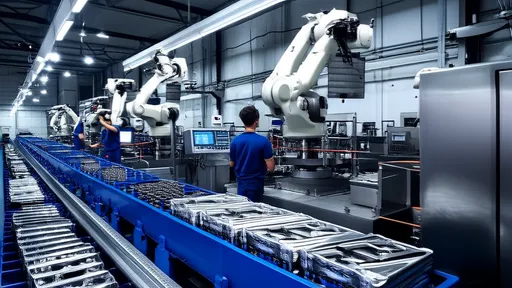

The human dimension of the Northvolt story is equally compelling. In a region historically dependent on mining and forestry, the battery factory has created approximately 3,000 direct jobs, with thousands more expected in the supply chain and supporting industries. The workforce represents a fascinating mix of local hires retrained from traditional industries and international experts drawn from across Europe and beyond. This fusion of local knowledge and global expertise has created what plant managers describe as a unique manufacturing culture—one that combines Swedish precision with startup innovation.

Technical innovation at the facility extends beyond the battery cells themselves. The manufacturing process incorporates artificial intelligence and machine learning systems that continuously optimize production parameters, improving yield and quality with each production cycle. Sophisticated battery management systems developed in-house allow for real-time monitoring of cell health and performance, providing valuable data that feeds back into the research and development process. This closed-loop approach to manufacturing intelligence represents what industry observers believe could become the new standard in advanced industrial production.

Supply chain considerations have been central to Northvolt's strategy from the beginning. The company has secured long-term agreements with Swedish mining companies for responsibly sourced raw materials, reducing dependency on potentially unstable international supply chains. This vertical integration extends to precursor materials, with Northvolt developing proprietary methods for producing cathode active materials—the most valuable components in lithium-ion batteries. This control over the entire production process, from raw materials to finished cells, provides Northvolt with significant competitive advantages in both cost and quality control.

The customer portfolio that Northvolt has assembled reads like a who's who of European automotive manufacturing. The company has secured $55 billion worth of contracts from manufacturers including BMW, Volkswagen, Volvo, and Polestar. These aren't merely supply agreements but deep technical partnerships that involve co-development of battery systems tailored to specific vehicle platforms. The collaborative nature of these relationships represents a shift from the transactional supplier relationships that have traditionally characterized the automotive industry.

Financing the Northvolt vision required unprecedented coordination between public and private capital. The company has raised over $6.5 billion in equity funding from investors including Goldman Sachs, Volkswagen, and BMW, alongside billions more in debt financing from European investment banks. Perhaps more significantly, Northvolt secured a $400 million investment from the European Union through the European Investment Bank—marking one of the largest direct investments the bloc has ever made in a private company. This level of support underscores the strategic importance European institutions have placed on developing indigenous battery manufacturing capability.

Environmental considerations have been integral to the factory's design and operation. Beyond its use of renewable energy, the facility incorporates sophisticated water recycling systems that reduce consumption by over 70% compared to conventional battery factories. The manufacturing process has been engineered to minimize solvent use and emissions, with advanced filtration systems ensuring that air and water leaving the facility are cleaner than when they entered. These environmental standards aren't merely regulatory compliance exercises but reflect Northvolt's fundamental business philosophy—that sustainable manufacturing can be commercially competitive.

The research and development activities at Northvolt extend well beyond current production needs. The company operates Northvolt Labs, a separate facility dedicated to next-generation battery technologies, including solid-state batteries and sodium-ion chemistry that could eventually reduce or eliminate dependency on scarce materials like cobalt. This forward-looking research program has attracted some of the world's leading battery scientists, creating what many describe as Europe's most concentrated pool of energy storage expertise.

Looking toward the future, Northvolt has already announced plans for additional gigafactories across Europe, with facilities planned in Germany and potentially elsewhere on the continent. The company's ambitious roadmap calls for 150 GWh of annual production capacity by 2030—enough to power approximately two million electric vehicles per year. This expansion would represent approximately 20% of the total battery production capacity projected to be needed in Europe by the end of the decade, positioning Northvolt as a central player in the continent's energy transition.

The success of Northvolt Ett has implications that extend far beyond the battery industry. The project demonstrates that Europe can still compete in capital-intensive, technology-driven manufacturing sectors where it had previously lost ground to Asian competitors. More importantly, it provides a template for how to build sustainable industrial capacity in the 21st century—integrating environmental considerations, advanced technology, and regional development in a cohesive strategy. As other European countries contemplate their own industrial transformations, the Northvolt model offers both inspiration and practical lessons.

In the broader geopolitical context, Northvolt's emergence comes at a critical moment. With tensions in global supply chains and increasing competition for strategic technologies, the ability to manufacture advanced batteries domestically has become a priority for economic security. Northvolt positions Europe to maintain control over a technology that will be as fundamental to the 21st century economy as oil was to the 20th. This strategic dimension explains why the project has received such strong support from European institutions and national governments alike.

As the first batteries roll off the production line at Northvolt Ett, they represent more than just energy storage devices. They embody Europe's determination to shape its industrial future rather than simply importing the technologies of the energy transition. The success of this ambitious venture will be watched closely by policymakers, industrialists, and environmentalists around the world—all wondering whether the Northvolt model might provide a blueprint for sustainable industrialization in the age of climate change.

The story of Northvolt is still being written, but the opening chapters suggest a compelling narrative of innovation, determination, and vision. In the cold northern light of Swedish Lapland, a new industrial champion is being born—one that could play a decisive role in powering Europe's clean energy future while demonstrating that environmental sustainability and industrial competitiveness can indeed go hand in hand.

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025

By /Nov 5, 2025